Today, we're diving into an industry game-changer—the flexible conveyor system. This revolutionary solution is tailor-made for lightweight products like those in the cosmetics industry.

What is a Flexible Chain Conveyor?

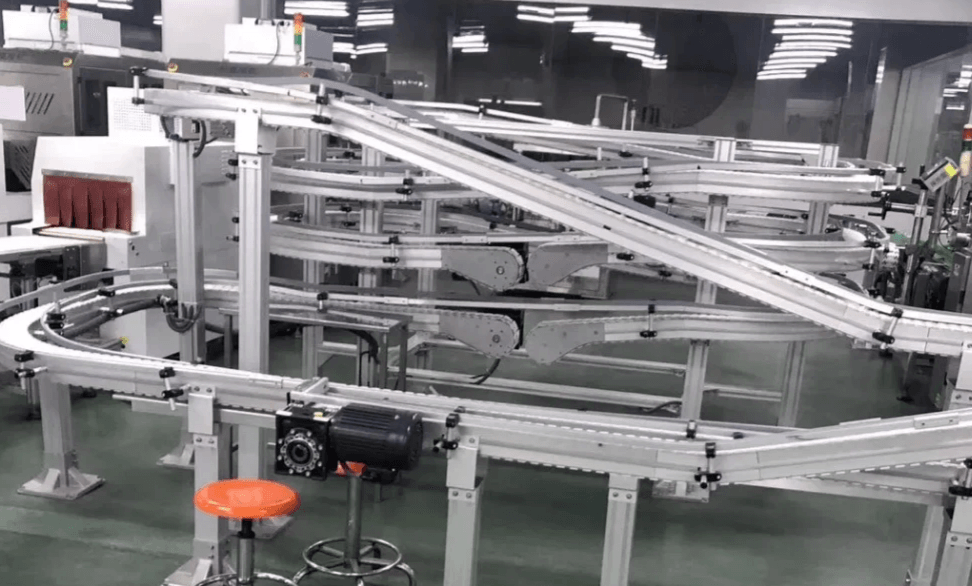

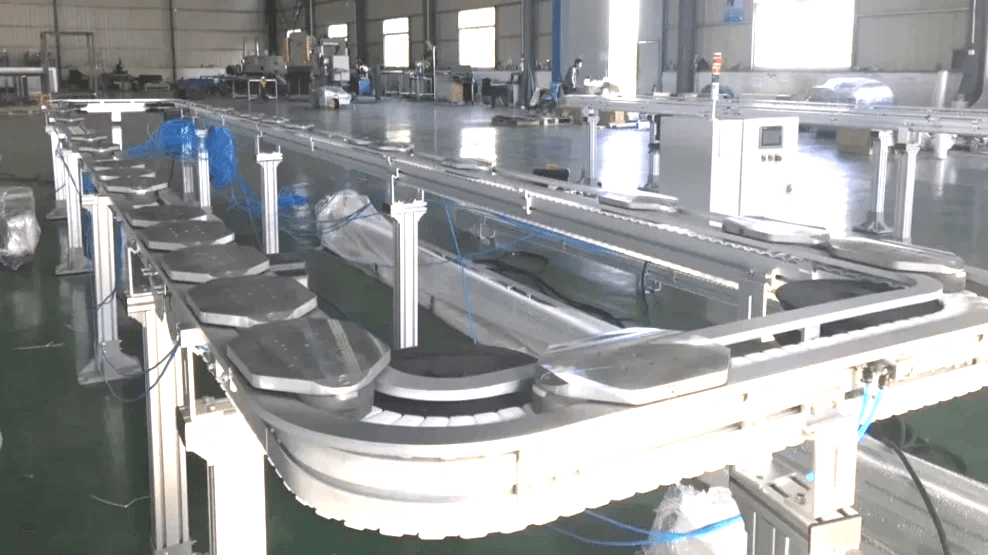

Picture this: a cosmetics factory bustling with tiny bottles, delicate packaging, and a need for precise, efficient transport. Enter the flexible chain conveyor. Imagine a series of interlinked chain plates, gliding along a track in a loop. Products are placed on these plates and whisked away to their destinations with ease.

Why the Cosmetics Industry Can't Do Without It?

Superb Flexibility:

Cosmetics come in a dazzling array of shapes and sizes, and production lines can be labyrinthine. The flexible conveyor is like a nimble dancer, effortlessly navigating complex routes. It can handle horizontal, vertical, and curved paths, making the most of every inch of factory space, especially in those tight spots.

Perfect Partner for Lightweight Products:

Most cosmetics—think bottles of perfume, tiny eye cream jars—are lightweight. The conveyor's lightweight chain plates ensure a gentle ride, with no risk of squashing or damaging these delicate items.

Precise, Flawless Transport:

In the cosmetics world, precision is king. A small error in product placement can spell disaster. Flexible chain conveyors are equipped with precise control systems that deliver each item to its exact destination. From the filling station to the packaging bench, every product arrives right where it should be.

Easy-Clean for Top Hygiene:

The cosmetics industry demands top-notch hygiene. The conveyor's chain plate design and materials make it a breeze to clean, ensuring a pristine transport process even if there's a spill or dust accumulation.

How Does It Work?

The magic lies in its simple-yet-brilliant design. A motor powers the chain, and the chain plates move along the track. Products sit on these plates and travel along with them. And the best part? The speed is adjustable. Whether you need a fast-paced, high-volume production run or a slow, meticulous process for a custom batch, it adapts seamlessly.

What Can It Do for a Cosmetics Factory?

Skyrocketing Efficiency:

With a flexible chain conveyor, cosmetics production efficiency soars. Products flow continuously and quickly between processes, eliminating the time and errors of manual handling. This means more products can hit the shelves faster.

Cost Savings Galore:

Despite its impressive capabilities, this conveyor is budget-friendly. It slashes labor costs and, thanks to its simple, durable design, maintenance is a breeze. No frequent part replacements or complicated upkeep. Over time, that adds up to significant savings.