Modular Belt: A Comprehensive Guide for Industrial Efficiency

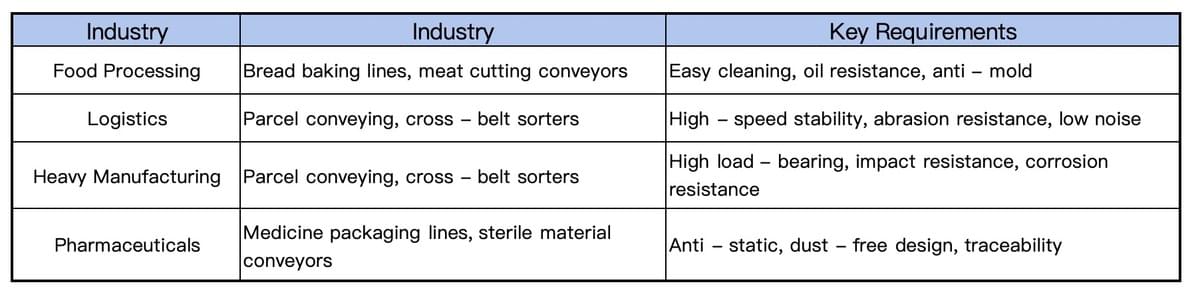

In the realm of industrial automation, the choice of conveyor system significantly impacts production efficiency and reliability. The Modular Belt has emerged as a highly favored solution across diverse sectors such as food processing, logistics, and heavy manufacturing. This article delves into the intricacies of modular belts, exploring their advantages, applications, and offering insightful tips for selection.

What Is a Modular Belt?

A modular belt is constructed from high - strength plastic modules interconnected via a hinge structure, forming a flexible conveying surface. Its defining characteristics are as follows:

- Modular Design: Enables versatile layouts, including straight, curved, and spiral configurations.

- Food - Grade Materials: Utilizes FDA - certified engineering plastics like PP and POM, which are resistant to acids and alkalis.

- High Load - Bearing Capacity: Can support up to 500kg per single point, making it suitable for heavy - duty material handling.

When compared to conventional PVC belts, modular belts boast a 60% reduction in maintenance costs and a lifespan three times as long.

Core Advantages of Modular Belts

Ease of Cleaning and Hygiene: The seamless surface allows for thorough cleaning, meeting the HACCP standards in the food industry. The easy - to - disassemble design cuts cleaning time by 80%, minimizing downtime.

High Adaptability and Durability: Effective within a temperature range of - 40°C to 100°C, it is well - suited for extreme environments like freezing and baking. With excellent impact resistance, it can withstand instantaneous impacts of up to 1.5 tons, making it ideal for automotive parts production lines.

Flexible Expansion and Low Maintenance: In case of module damage, only the affected parts need replacement, eliminating the need to replace the entire belt. The minimal lubrication requirement reduces maintenance costs to one - third of that of traditional chains.

Case Study: A food company enhanced production efficiency by 35% and saved over 500,000 yuan annually on maintenance costs by implementing modular belts.

5 Key Considerations for Selecting Modular Belts

Material Selection:

- PP (Polypropylene): Acid and alkali resistant, cost - effective, suitable for light - load scenarios.

- POM (Polyoxymethylene): High - strength and wear - resistant, ideal for heavy - duty and high - speed conveying.

- PE (Polyethylene): Highly flexible, performs well in low - temperature freezing environments.

Module Specifications:

- Pitch (Pitch): Available in 12.7mm, 25.4mm, 50.8mm, etc., determines conveying accuracy.

- Width Range: From 50mm to 2000mm, must match production line dimensions.

Drive Mechanism:

- Sprocket Drive: High - precision and low - noise, suitable for cleanrooms.

- Sprocket Drive: High - torque, ideal for heavy - load applications.

#modularbelt# belts conveyor #conveyor systems